Commercial Metal Detectors vs GPR: What’s Best for Your Job Site?

Published by Audrey Floyd on 06/04/25

When you need to know what's underground, choosing the right detection technology can mean the difference between a successful project and a costly mistake. Whether you're a contractor avoiding utility strikes, an archaeologist preserving historical sites, or a property manager locating buried infrastructure, understanding your options is crucial.

This guide breaks down the three main categories of underground detection tools: hobby metal detectors, commercial metal detectors, and Ground Penetrating Radar (GPR). We'll help you understand the capabilities and applications of each technology so you can make the right choice for your specific needs.

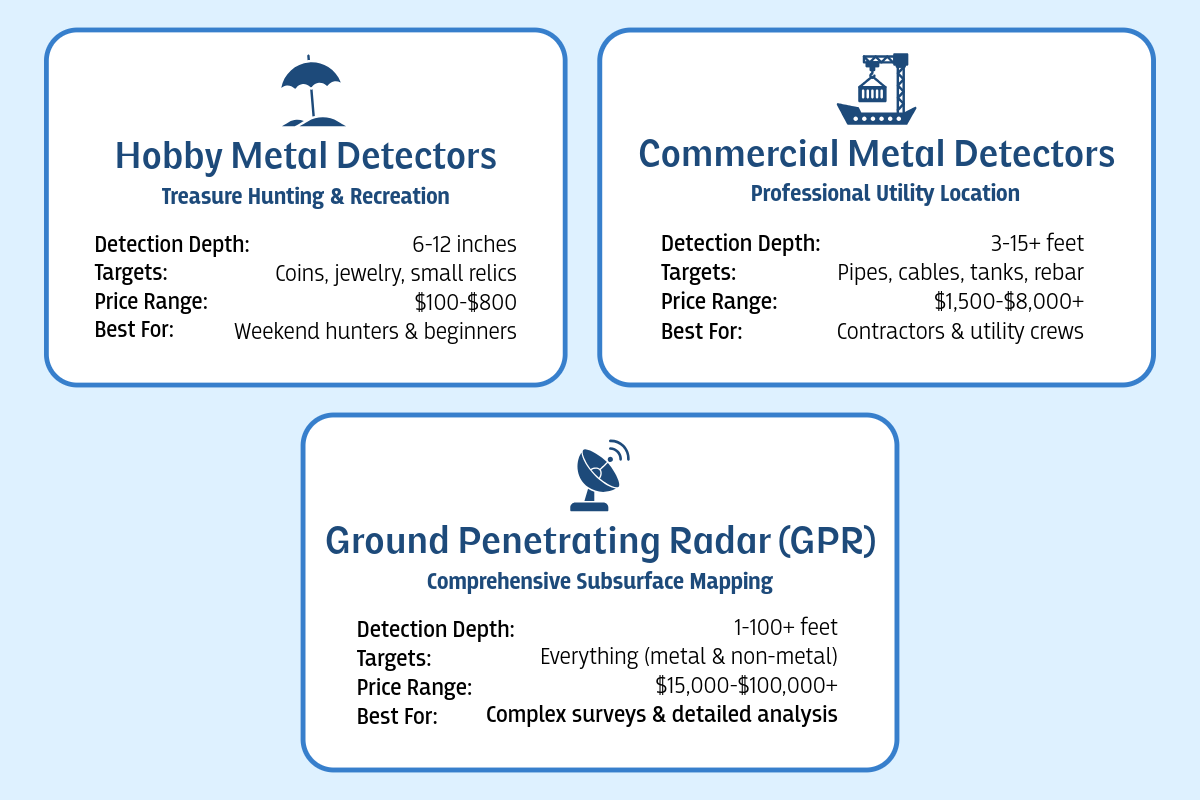

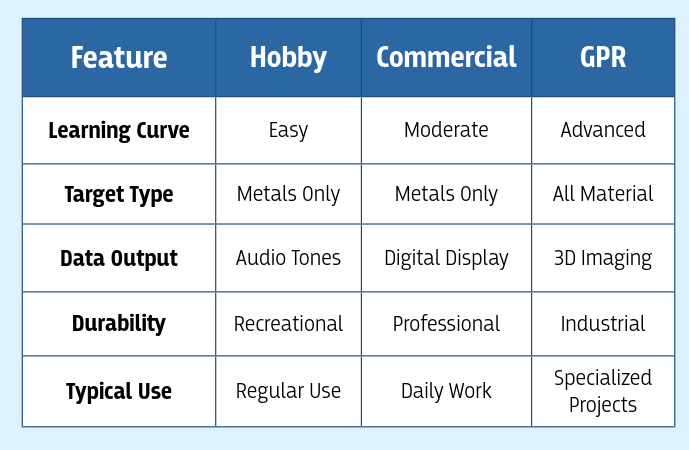

The Three Technologies: At a Glance

As you can see in the comparison above, each detection technology serves different purposes and applications. Understanding these fundamental differences is the first step in determining which technology aligns with your specific needs.

Understanding Hobby Metal Detectors

Hobby detectors serve their intended market well but have specific design parameters that limit their professional applications:

Depth Capabilities: Most hobby detectors are optimized for finding smaller objects near the surface. They excel at locating coins, jewelry, and relics in the top 12 inches of soil but aren't designed for deeper professional applications.

Target Identification: These detectors provide basic audio signals and simple visual displays. They can distinguish between general categories like ferrous and non-ferrous metals but lack the sophisticated discrimination needed for complex professional environments.

Construction: Built for recreational use, hobby detectors prioritize portability and ease of use over the rugged durability required for daily professional work.

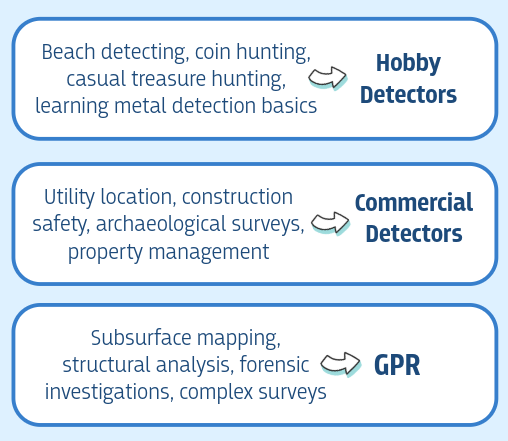

Applications: Perfect for weekend treasure hunting, beach detecting, coin shooting, and casual relic hunting where precision depth and advanced discrimination aren't critical factors.

Commercial Metal Detectors: Professional Capabilities

Commercial metal detectors are engineered specifically for professional applications where accuracy, reliability, and efficiency are essential.

Key Characteristics:

Enhanced Detection Depth: Commercial detectors can locate large metal objects at significant depths, with some capable of detecting large targets 15 feet or more underground, depending on soil conditions and target size.

Advanced Signal Processing: Professional-grade discrimination helps distinguish between different types of metals and provides more accurate target size and depth estimation.

Durable Construction: Built to withstand daily professional use in challenging environments including construction sites, varying weather conditions, and demanding work schedules.

Professional Features: Many commercial detectors include features like GPS integration, data logging, wireless connectivity, and compatibility with mapping software.

Typical Applications:

- Construction & Contracting: Locate rebar, conduit, and buried utilities before excavation

- Utility Companies: Mark underground gas, water, and electrical lines

- Municipalities: Safety verification during road work and infrastructure projects

- Archaeological Surveys: Detect metal artifacts while minimizing site disturbance

- Environmental Consulting: Locate buried tanks and support contaminated soil investigations

- Agriculture: Find buried equipment, fencing, and irrigation systems on large properties

Ground Penetrating Radar: Comprehensive Subsurface Imaging

GPR technology provides detailed subsurface information regardless of material composition, making it valuable for applications requiring comprehensive underground mapping.

GPR Capabilities:

Material Versatility: GPR detects both metallic and non-metallic objects including plastic pipes, concrete structures, voids, and changes in soil composition.

Detailed Imaging: Provides 2D and 3D subsurface maps showing exact locations, depths, and spatial relationships between underground features.

Diverse Applications: Suitable for archaeological surveys, concrete inspection, geological studies, utility mapping, and structural analysis.

Real-Time Display: Modern GPR systems show subsurface conditions in real-time, enabling immediate assessment and decision-making.

GPR Considerations:

Soil Dependency: Performance varies based on soil conditions. Clay-rich or highly conductive soils can limit penetration depth and image clarity.

Investment Level: Higher initial equipment cost and training requirements compared to metal detection technologies.

Operational Complexity: Requires specialized knowledge to operate effectively and interpret results accurately.

Data Processing: Many applications benefit from post-processing and detailed analysis to extract actionable information.

Application-Based Technology Selection

The choice between detection technologies depends on your specific requirements:

Commercial Metal Detectors Excel When:

- Primary targets are metallic (pipes, cables, tanks, rebar)

- Speed and simplicity are operational priorities

- Routine utility marking comprises most detection work

- Real-time audio feedback meets project requirements

- Working in soil conditions that may limit GPR effectiveness

GPR Is Optimal When:

- Detecting both metallic and non-metallic objects is necessary

- Detailed subsurface mapping is required for project planning

- Archaeological or forensic applications demand comprehensive site analysis

- Structural assessment of concrete, pavement, or foundations is needed

- Comprehensive documentation and reporting are project requirements

Multiple Technologies May Be Appropriate When:

- Diverse project types require different detection capabilities

- Large-scale infrastructure projects benefit from comprehensive subsurface knowledge

- Risk mitigation justifies investment in multiple detection methods

- Service offerings require the most comprehensive detection capabilities

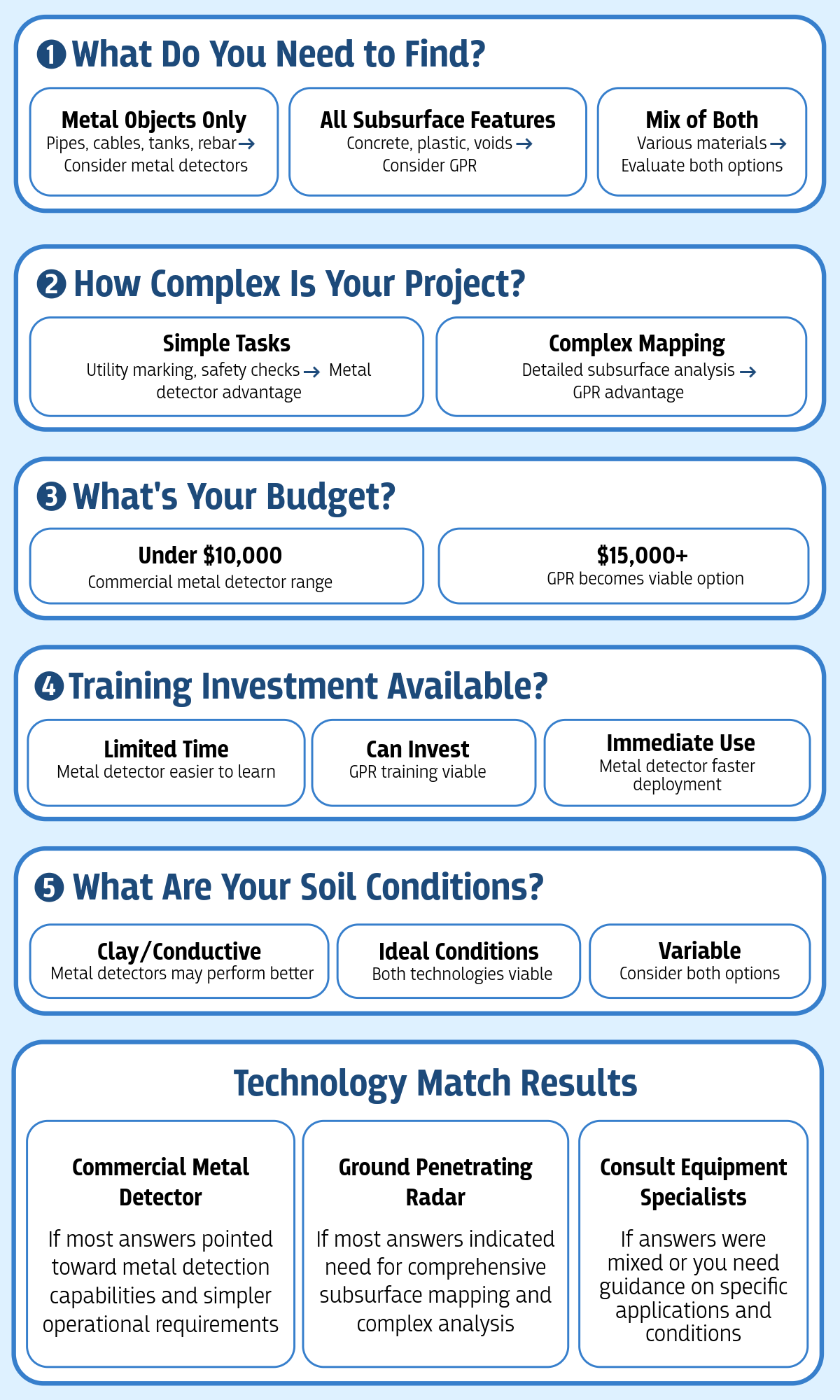

Decision Framework: Matching Technology to Needs

This systematic approach helps evaluate the best technology for your applications. Let's examine each step in detail:

Step 1: Define Detection Requirements

- What materials need to be detected? (metals only vs. all subsurface features)

- What target sizes are typical? (small utilities vs. large infrastructure)

- What depths are involved? (shallow vs. deep detection requirements)

Step 2: Evaluate Project Complexity

- Simple location tasks may be well-served by metal detection

- Complex mapping requirements may necessitate GPR capabilities

- Documentation needs influence technology selection

Step 3: Consider Operational Factors

- Available training time and resources

- Frequency of use (daily, weekly, occasional)

- Environmental conditions where equipment will be used

Step 4: Assess Budget Parameters

- Total investment capacity (equipment, training, support)

- Rental vs. purchase considerations for project-specific needs

- Return on investment expectations and timeline

Step 5: Evaluate Site Conditions

- Typical soil types in your operating area

- Environmental factors that may affect performance

- Access and portability requirements

Common Technology Misconceptions

"GPR Always Provides Superior Results"

Reality: GPR performance varies significantly based on soil conditions. In certain environments, metal detectors may provide more reliable results for metallic targets.

"Commercial Detectors Are Simply Upgraded Hobby Models"

Reality: Commercial detectors use different technologies and design principles, offering capabilities specifically engineered for professional applications.

"Maximum Depth Is the Most Important Factor"

Reality: Reliable target identification at working depths often matters more than maximum theoretical detection depth.

"GPR Is Too Complex for Most Applications"

Reality: Modern GPR systems feature improved user interfaces and automated functions, though interpreting complex results still requires appropriate training.

"One Technology Handles All Detection Needs"

Reality: Each technology has specific strengths, and many organizations benefit from having multiple detection capabilities available.

Investment Considerations

For Most Professional Applications:

Commercial metal detectors often provide an effective balance of capability, cost, and operational simplicity for applications primarily involving metallic targets.

For Specialized Requirements:

GPR becomes essential when non-metallic detection, detailed mapping, or comprehensive subsurface analysis are regular project requirements.

For Comprehensive Operations:

Organizations handling diverse project types may benefit from maintaining multiple technologies, using each for applications that match their specific strengths.

Implementation Guidance

Before Making Your Decision:

- Document Your Specific Use Cases: Identify the detection tasks you'll perform most frequently

- Analyze Your Operating Environment: Understand typical soil conditions and site constraints

- Evaluate Training Requirements: Consider available time and resources for learning new technology

- Establish Your Budget Parameters: Include equipment, training, and ongoing operational costs

- Consider Trial Options: Explore rental or demonstration opportunities before major purchases

Working with Detection Equipment Specialists:

Equipment specialists can provide valuable support including:

- Application-specific demonstrations tailored to your needs

- Performance assessment based on your typical operating conditions

- Training recommendations and ongoing technical support

- Rental programs for project-specific requirements

- Equipment upgrade pathways as your needs evolve

Conclusion: Informed Technology Selection

Choosing between hobby detectors, commercial metal detectors, and GPR requires careful consideration of your specific applications, operating environment, and resource availability. Each technology serves distinct purposes and excels in different scenarios.

Commercial metal detectors provide professional-grade performance for applications primarily involving metallic targets, offering advanced capabilities while maintaining operational efficiency.

GPR technology delivers comprehensive subsurface information essential for complex projects requiring detailed mapping or detection of both metallic and non-metallic features.

The optimal choice depends on honest assessment of your detection requirements, realistic evaluation of operational constraints, and clear understanding of each technology's capabilities and limitations.

Ready to explore your options? Consulting with detection equipment specialists can help you evaluate how different technologies align with your specific applications, operating conditions, and budget parameters, ensuring you select the solution that delivers optimal results for your detection needs.